FAQs

General Questions

|

How can I learn more about the DYEC? |

|

There are many opportunities to learn more about the DYEC. This website provides information on facility operations and test results. Residents can also check out the Education and Resources section for more information, take a virtual tour or join our contact list to be notified about upcoming activities. |

|

Where is the DYEC located? |

|

The DYEC is located at 1835 Energy Drive, Clarington, Ontario. |

|

Who owns the DYEC? |

| The DYEC is 100 per cent publicly owned by Durham and York Regions. Durham Region owns 78.6 per cent of the facility and delivers 110,000 tonnes of garbage/year while York Region owns 21.4 per cent and delivers 30,000 tonnes of garbage/year. |

|

Why did Durham and York Regions choose Energy from Waste? |

|

In 1998, the Durham Region Works Committee directed the formation of two committees, comprised of staff and residents, to recommend strategies for managing all residential waste in Durham Region from the year 2000 to 2020. These Committees proposed the Long Term Waste Management Strategy Plan that was endorsed by Durham Regional Council. Recommendations made included the investigation of Energy from Waste (EFW) as an alternative to landfill for final disposal of residential garbage remaining after diversion. In 2005, both Durham and York Regions started a joint Environmental Assessment (EA) that included extensive public consultation to determine the preferred alternative for managing residential garbage that remains after diversion taking into account social, environmental and economic factors. EFW was selected as the most environmentally sound, sustainable and cost-effective solution. This solution was approved by both Durham and York Regional Councils in 2006. The EA was completed in 2009 and approved by the Ontario Ministry of the Environment, Conservation and Parks (MECP) in 2010. |

|

How does the DYEC benefit Durham and York Regions? |

|

The DYEC provides many benefits to Durham and York Regions, such as:

|

Waste Diversion

|

How much garbage is processed at the DYEC? |

|

The Environmental Compliance Approval (ECA) for the DYEC currently allows the facility to process up to a maximum of 140,000 tonnes of waste per year for disposal at the site. The Regions are proposing to increase this amount by 20,000 tonnes per year for a total of 160,000 tonnes of waste per year. The facility is capable of processing 160,000 tonnes with its current equipment and is currently being underutilized despite demand for additional waste capacity for residential waste disposal within the Regions. Visit increasing Capacity to 160,000 for more information on the 2019 Streamlined Environmental Assessment. |

|

How many trucks will come to the DYEC each day? |

|

The average number of trucks arriving daily to the DYEC is 24. This is a combination of garbage delivery, supply trucks, and residual waste removal trucks. |

|

Is garbage from other municipalities or sectors (industrial, commercial and institutional) processed here? |

|

No. The approved Environmental Assessment (EA) and Environmental Compliance Approval (ECA) for the DYEC specifically directs that only household waste remaining after Durham Region's and York Region's aggressive composting, recycling and reuse program, collected by our waste collection operators, can be received and processed at this facility. Therefore, the DYEC does not accept garbage from other municipalities, sectors or private haulers. |

|

How does Energy from Waste fit in with other waste diversion programs? |

|

The solid waste management hierarchy illustrates the preferred order for managing waste to minimize its environmental impacts. The most important steps are to reduce, reuse, recycle and compost. The next step is to recover which refers to the recovery of energy and additional metals from residential garbage. While energy recovery is important, Durham and York Regions are first committed to improving waste diversion rates through reuse, recycling and composting programs. Disposing waste into landfill is the least desirable option for managing waste. |

|

Do you pre-sort waste before processing at the DYEC? |

|

There are many hands that pre-sort residential waste as it travels from homes and ends up as garbage at the DYEC:

|

Cost and Operations

|

How much did the DYEC project cost? |

|

The gross capital costs for the DYEC project amount to $284.2 million; this includes $255 million for construction of the facility and approximately $29 million for the Environmental Assessment, permitting and approvals, site servicing, consulting fees and economic development activities in the host community of Clarington. |

|

How much does it cost to operate the DYEC? |

|

The gross annual operating costs are approximately $16.8 million (2020 dollars). This cost is shared by Durham and York Regions based on the quantity of waste each Region delivers to the DYEC. |

|

How are the costs funded? |

|

Durham Region's portion of the DYEC project capital costs were funded by the Federal Gas Tax. The operating costs are funded through:

|

|

Who is responsible for the day-to-day operations? |

|

Covanta was selected to design, build, operate and maintain the DYEC. Covanta employs approximately 40 full-time, highly qualified staff to operate the facility under the Regions' supervision for a 20-year contract term, plus optional term extensions of up to 10 years. Regional staff work on-site at the DYEC to oversee the facility and maintain on-going communication and documentation with Covanta's facility operators. Regional staff ensure that Covanta: (i) abides by the conditions of the Ministry of the Environment, Conservation and Park's Environmental Compliance Approval and other applicable regulatory requirements; (ii) meets the contract terms for operations, maintenance and environmental performance outlined in the Project Agreement; and (iii) meets public expectations and operates the facility to the highest standards. |

|

What are the DYEC's hours of operation? |

|

The facility operates 24 hours a day, 7 days a week, with periodic scheduled shutdowns for maintenance activities. Garbage deliveries are limited to Monday through Saturday, 7 am to 7 pm. |

Energy from Waste (EFW) Technology

|

What is EFW? |

|

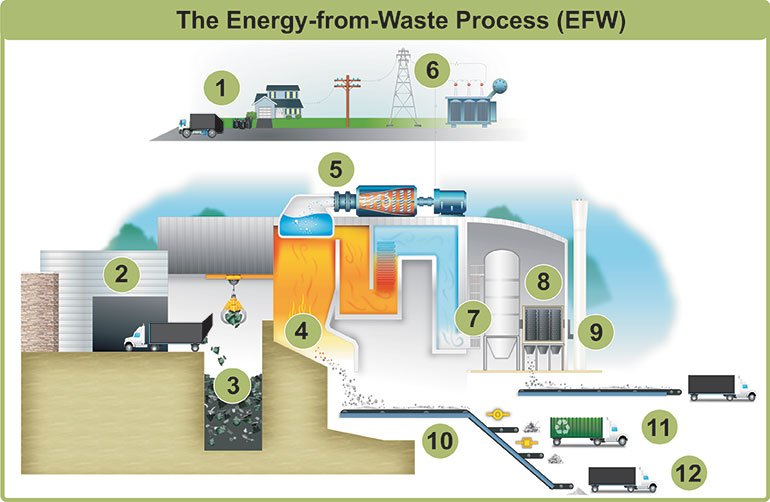

EFW is a highly technical process that takes garbage and combusts (burns) it at extremely high temperatures (greater than 1,000°C). The resulting thermal energy (heat) produces steam, which turns a turbine generator to produce electricity. After the garbage is completely burned, metal can be recovered and recycled from the ash that remains, reducing the need to mine raw materials to make new products. |

|

What is the difference between an EFW facility and an incinerator? |

|

Modern EFW facilities differ from incinerators of the past which were designed to do one thing – reduce the volume of garbage requiring disposal. Garbage was processed using uncontrolled burning with minimal to no air pollution control systems. They did not recover energy or any other value from the garbage material. In contrast, modern EFW facilities burn garbage in a highly controlled and efficient combustion system, recover energy and metals from the combustion process and are equipped with proven air emission control technologies that reduce emissions to safe levels in accordance with strict regulatory requirements. |

|

How is garbage processed at the DYEC to generate energy? |

|

Take our virtual tour to learn how garbage is processed to make energy . Some of the key stages of the EFW process are outlined in the diagram and description below:

|

|

What is left after garbage is processed? |

|

The EFW process reduces the volume of residential garbage by approximately 85 to 90 per cent. The largest portion of the end products is an inert, non-hazardous bottom ash, which resembles crushed rock. The smaller portion is fly ash with lime and carbon residue which is captured in the air pollution control equipment. Fly ash is treated onsite with a pozzolanic material, cement and water to bind or stabilize materials to render it inert and non-hazardous. Bottom ash and treated fly ash are transported to landfill and used as daily cover material. Ash at the DYEC is tested to ensure that it is non-hazardous before being shipped offsite. Metals are recovered for recycling after the combustion process. The revenue from this material helps to offset the operating cost of the facility. |

|

How much energy is produced at the DYEC and what is it used for? |

|

The DYEC generates approximately 14 megawatts (MW) of net electrical energy on a continuous basis, which is enough to power about 10,000 homes per year. The electricity is sold to the Provincial grid as base load energy at the guaranteed price of $0.08 per kWh inflation indexed for a 20-year term. In the future, steam from the DYEC may be used for district heating within the Clarington Energy Park located adjacent to the facility. The steam produced could heat the equivalent of 2,200 homes per year. |

Health and Environment

|

Is the DYEC safe? |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Yes. The DYEC operates under some of the most stringent air emission guidelines in the world. Human health and the environment are primary concerns for both Durham and York Regions. The Regions have undertaken a series of detailed studies on air emissions, health, traffic, noise, ground and surface water to assess any potential effects from the DYEC to ensure that residents and the environment are protected. Results of the Human Health and Ecological Risk Assessment studies in the Environmental Assessment concluded that the DYEC would not lead to any adverse health risks to the public or environment. |

||||||||||||||||||||||||||||||||||||||||||||||||

|

How can I access emissions data for the facility? |

||||||||||||||||||||||||||||||||||||||||||||||||

|

The gases generated in the EFW process are sampled continuously using state-of-the-art technology; this is referred to as continuous emissions monitoring or CEM. Monitoring emissions ensures that the DYEC continues to comply with stringent environmental monitoring and mitigation plans, standards and guidelines set out by the facility's Environmental Compliance Approval (ECA) granted by the Ontario Ministry of the Environment, Conservation and Parks (MECP). The Regions also conduct two emissions (source/stack) tests annually to verify the facility is operating below the air emission limits established in the ECA. Results of all emissions testing are posted on this website. |

||||||||||||||||||||||||||||||||||||||||||||||||

|

What are the ECA limits for air emissions at the DYEC? |

||||||||||||||||||||||||||||||||||||||||||||||||

|

To ensure the DYEC operates under some of the most stringent air emission guidelines in the world, the facility often operates within stricter limits than the province allows. Emissions limits for the DYEC, as shown in the table below, are either more stringent or meet the guidelines set out by the Province (Ontario Guideline A-7).

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Does the DYEC impact climate change? |

||||||||||||||||||||||||||||||||||||||||||||||||

|

EFW is recognized as a net reducer of greenhouse gas emissions by the Global Roundtable on Climate Change (GROCC), the Intergovernmental Panel on Climate Change (IPCC), the U.S. Environmental Protection Agency (U.S. EPA), the Kyoto Protocol and the European Union due to the following:

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Does the DYEC generate odours? |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Waste is brought to the DYEC in large highway-hauler trucks that must be covered. The trucks enter the tipping floor and the doors are closed before any waste is offloaded. Since this part of the building is under negative air pressure, air and odours do not escape when the doors are opened to allow trucks to enter and exit the tipping floor. Odours are not emitted from the DYEC stack. Due to the high combustion temperatures, all sources of odour are destroyed inside the sealed boiler. |

Public Outreach

|

How can I learn more about the DYEC? |

|

Residents from both Durham and York Regions have many opportunities to be involved and stay informed, including attending public meetings. Check out the Education and Resources section for more information or join our contact list to be notified about upcoming activities. |

|

I would like to book an educational tour of the DYEC; how do I do this? |

|

Educational Tours for school groups, post-secondary programs and industry groups are available but must be scheduled in advance. Please request to book a tour. |